Energy efficiency & decarbonization global project

Objective

The objective of the Campari Group is to extend the energy efficiency and decarbonization path to all the facilities and create a multi-year project pipeline for each production site.

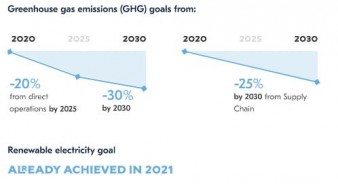

The targets on Energy and GHG emissions are:

- Reduce Green House Gases (GHG) emissions from direct operations by 20% in 2025, by 30% in 2030, and from the total Supply Chain by 25% in 2030, using 2019 as a baseline.

- 100% renewable electricity for European production sites by 2025, a target already achieved in 2021 (3 years ahead!)

Description

In 2020, Campari Group launched a global multiyear programme to develop energy saving initiatives, implement sustainable solutions and improve energy consumption. In 2021 and 2022 it proceeded with several interventions and investments to:

- Decarbonize its facilities. As part of the 2021 agenda, a series of thermal recovery activities were carried out at the distillery in US (Lawrenceburg, Kentucky) and a new natural gas boiler was installed in the Mexican distillery of Arandas, replacing the old fuel oil one. The internal on-site energy audit programme continued with the assessment of the Novi Ligure (Italy) site.

- Sourcing renewable energy in the European operations has been one of the key management approaches. In 2021 the Group extended the renewable origin of purchased electricity to all European production plants and headquarters in Sesto San Giovanni, through the attainment of a Guarantee of Origin.

- Last May 2021, the company launched its first share buyback programme which included a contractually-agreed reward mechanism: an amount deriving from the outperformance in the purchase cost of the shares during the Programme is going to be allocated by Campari Group to the installation of photovoltaic panels in Campari’s main plant located in Italy (Novi Ligure and Canale). A similar programme has been launched in 2022, through which part of the outperformance will be invested in the installation of photovoltaic panels in the Group’s plants in Jamaica.

Results

- The Campari Group energy efficiency and decarbonisation programme initiatives, the improved efficiency in the distillation processes and the increase in production volumes resulted in a reduction of the Group’s energy consumption per litre manufactured to 1.95 MJ/L, an overall of -24% compared to the previous year (2.57 MJ/L) and of -28% compared to 2019 (2.69 MJ/L).

- The quantity of carbon dioxide-equivalent emitted per litre manufactured was reduced to 0.11 Kg/L, an overall -21% compared to 2020 (0.14 Kg/L) and overall -27% compared to 2019 (0.15 Kg/L).

Measurement & evaluation

From 2013 the QHSE policy has been adopted and applies to all company locations and divisions.

The Group’s environmental performance is certified through international standards (ISO14001/EMAS/ISO50001).

Campari Group has set up a structure dedicated to control environmental pollution, waste, and water disposal and defined and disclosed specific environmental targets aligned with the UN SDGs to be reached by 2025 and 2030.

Website

https://camparigroup.com/en/page/sustainability/environment Downloads

Downloads

Photo gallery

Documents